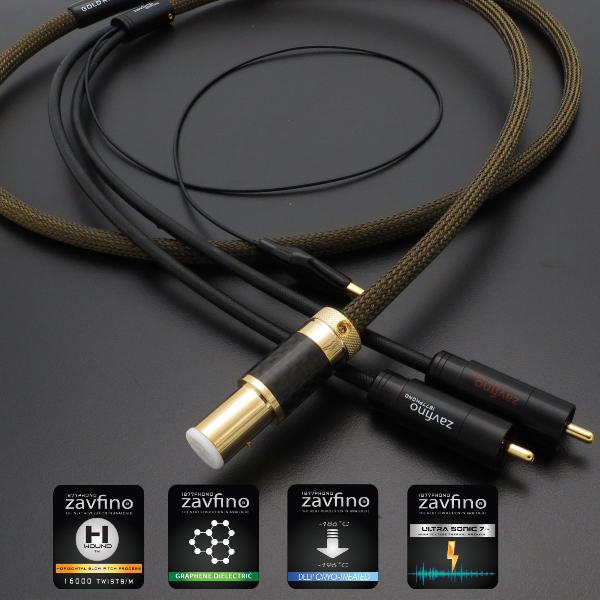

The Mahone tonearm cable was carefully designed and manufactured using fine strand OCC copper coated in a PE dielectric. All 4 cores are evenly matched with an identical conductor count and conductor size. After extrusion the cores are tightly twisted followed by a mylar/copper drain shield for maximum EMI/RFI rejection.

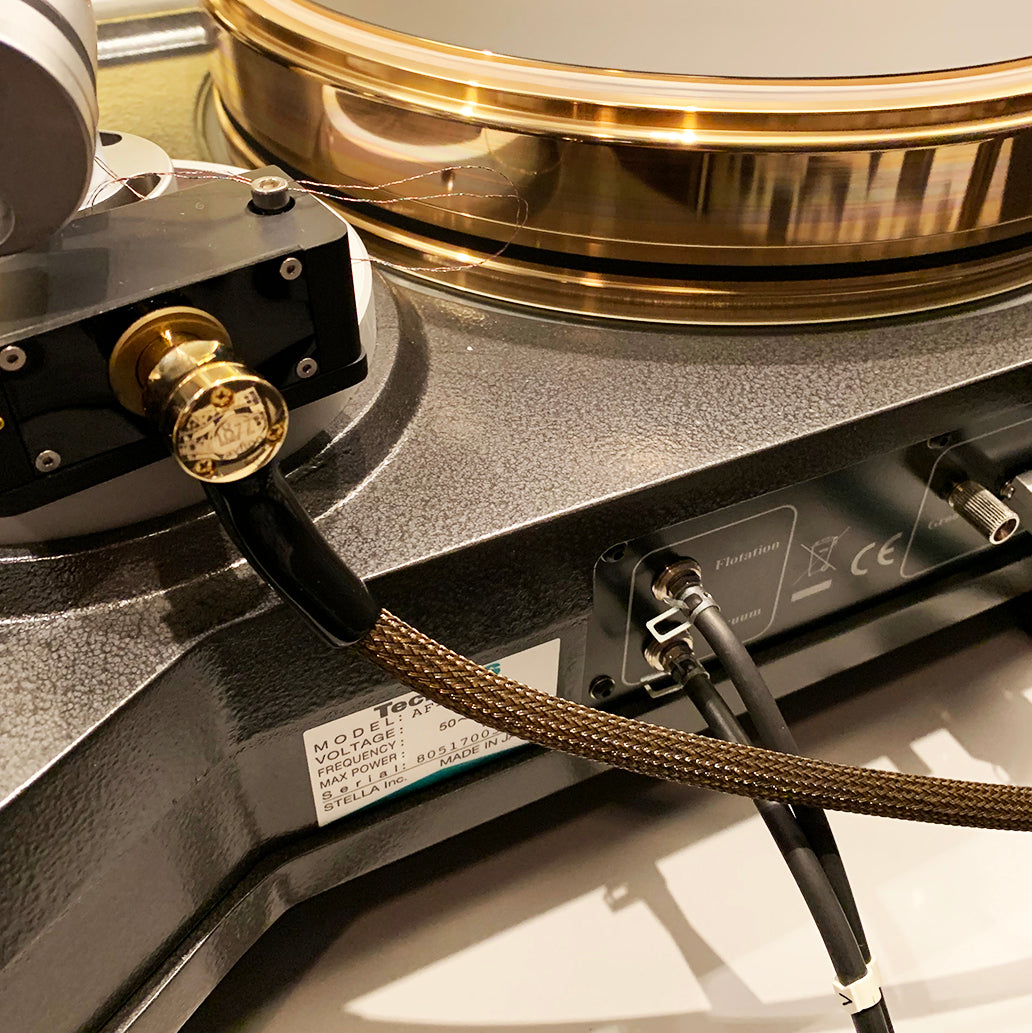

The Mahone comes standard with our ZV-88 straight DIN, or TAD-2R 90˚ DIN for right angle terminations.

The Mahone provides crystal clear transfer, portraying Jazz vocals controlled but natural and presenting classical performances with all the depth and diversity the composer intended.

The Mahone like all of our cables goes through our new Ultra Sonic cleaning process where we run the raw copper through a water bath that is super charged to burn away dirt, oil, particles and impurities on the surface of the wire. This Ultra Sonic Bath also has the added unique effect of giving our cables a pre-burn sound that could take hundreds of hours to achieve through normal use.

SPECIFICATION● Conductor: OCC Conductors, tight pitch construction. low capacitance, shielded

● Insulations: PE dielectric, PTFE dielectric, Nylon sleeve, 80˚C PVC jacket

● Shield: Aluminum mylar with silver coated copper tight pitch spiral

● Ground: 50cm OFC ground wire with 24k gold plated ground clip

● Connector Female (DIN): 1877 ZAV-88 straight or TAD-3R right angle DIN, 24k gold plated high purity copper insulated in PTFE/Tef utilizing 1877 anti-stress pin construction.

● Connector Male (RCA): 1877 ZSP4 with OCC copper pin assembly in 24k gold,

● Sleeve 1: Polyethylene terephthalate(PET) monofilament sleeve combined with high tension abraision resistent nylon

All of the conductors used in our cables undergo Deep Cryo™ treatment before the insulation is extruded over the metals. Our research has proven that the conductor—and only the conductor— benefits from cryo-treatment. Materials such as polyvinyl chloride (PVC™), Teflon™, PE, and Silicon™ can all be adversely affected by cold-temperature annealing. Cryo-treating non-conductors and insulating materials can cause them to break down and become brittle.

The purity, size, and molecular structure of each conductor determine the specific temperature within the -186ºC to - a 196ºC range that we cryo-treat it at. Zavfino’s research into cold temperature physics has proven that the absolute lowest temperature is not necessarily the best for cryo-treatment.

This is a two-stage process. In the first stage we draw the bare conductor through a ceramic die into an ultrasonic cleaning chamber that bombards the conductor with multiple ultrasonic frequencies. This emulsification process removes all debris from the surface of the wire down to the molecular level and leaves absolutely zero residues.

UltraSonic 7 High Voltage / Thermal Break-in

This is a two-stage process. In the first stage we draw the bare conductor through a ceramic die into an ultrasonic cleaning chamber that bombards the conductor with multiple ultrasonic frequencies. This emulsification process removes all debris from the surface of the wire down to the molecular level and leaves absolutely zero residues. After each individual wire is processed, we strand it into bundles and then subject the bundles to further treatment. During the second stage of the ultrasonic burn-in, we increase the voltage to a higher level that’s just below the threshold of the conductor. This adjustment in temperature allows us to get a unique “break-in effect” normally associated with cables that have had 30 to 40 hours of signal and/or current run through them.