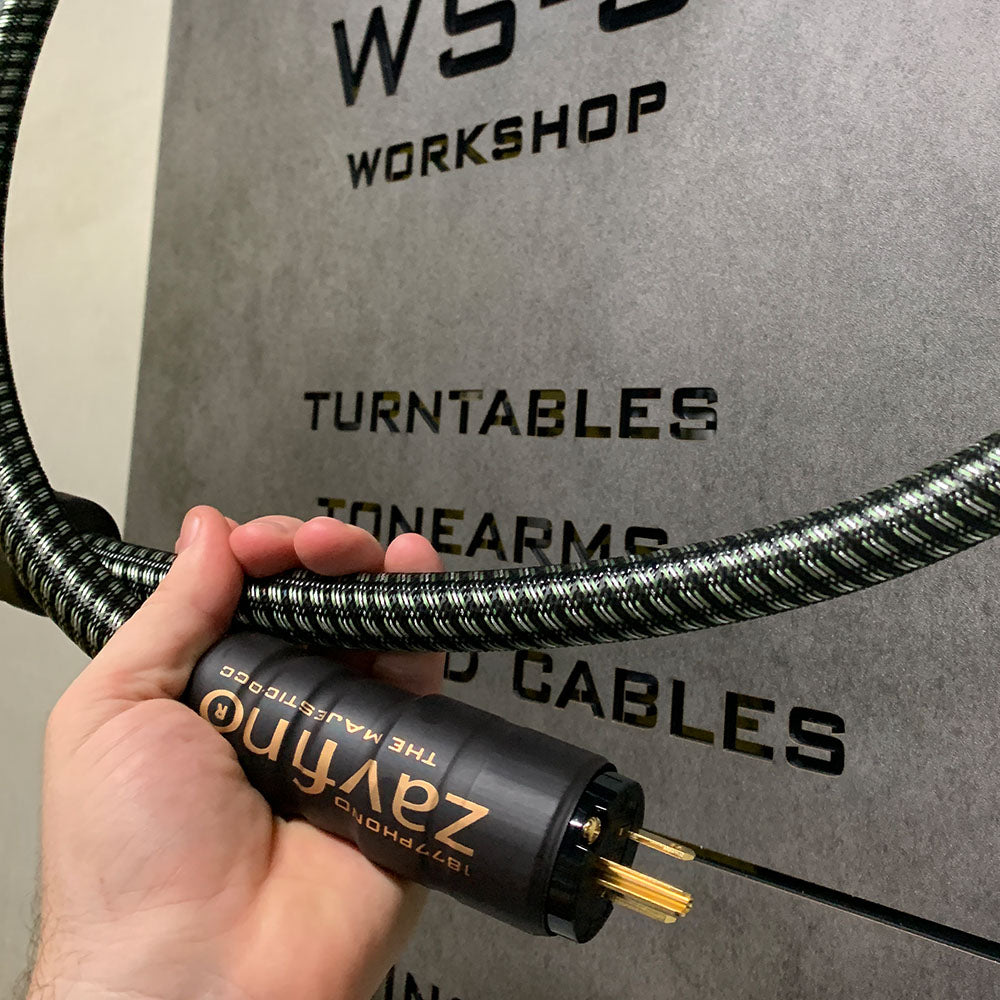

FINA MKII is a PC-OCC audiophile-grade power cable that brings together both high performance and exceptional value. Fina incorporates generously sized (3 x 14 AWG) PC-OCC conductors, which ensures that your audio components will receive optimal power delivery. Its high purity design is ideal for a large selection of source components and tube amplifiers, as well as integrated amps. Built with the same highest grade materials, geometry and construction techniques as its larger brother, The Majestic power cable, Fina differs only in using more modest-sized conductors. This makes Fina the natural complement to The Majestic power cable when used in a full-Zavfino power cable loom, where power demand dictates cable choice.

Zavfino uses on only the highest purity Japanese PC-OCC single crystal copper conductors in the Fina power cord. The 6N (99.9999%) Pure Copper (PC) Ohno Continuous Cast (OCC) copper is an extremely high quality audiophile grade conductor material and greatly appreciated for its inherent naturalness, inner warmth and absence of grain. Using a tight perfect pitch twist to construct the conductors, we deliver a no-compromise conductor with higher copper content per metre than many competing products. This tighter pitch compresses the conductor cores, which adds to the harmonically rich and complete sound Fina.

Great care goes into the preparation and production of Fina’s PC-OCC Conductors. To begin, before extrusion, the conductors are ultrasonically and thermally pre-cleaned and burned-in, which removes oil, residue and impurities that may be present after multi-stranding draw down. Then, once the variable size strands are twisted into the tight pitch finished 14 AWG individual core, it is subjected again to an ultrasonic thermal clean process, this time at an even higher voltage, eliminating any final impurities, which results in the unique pre-burn / broken-in sound inherent to Zavfino cables.

The 14 AWG PC-OCC ultrasonically cleaned bare conductors are directly sent through a pressure extruder that puts 105oC PVC insulation directly over the cores, sealing in the conductor in its purest state. Cotton filler insulation, a 100% drain shield and two braids; the first, an anti-static direct braid red polyester and; the second, a (PET) monofilament, finish off the cable before it is terminated with Zavfino’s very high quality and robust connectors.

The end result; Fina is a power cable that is dynamically impressive and open, harmonically rich and exceptionally quiet, bringing your music to life.

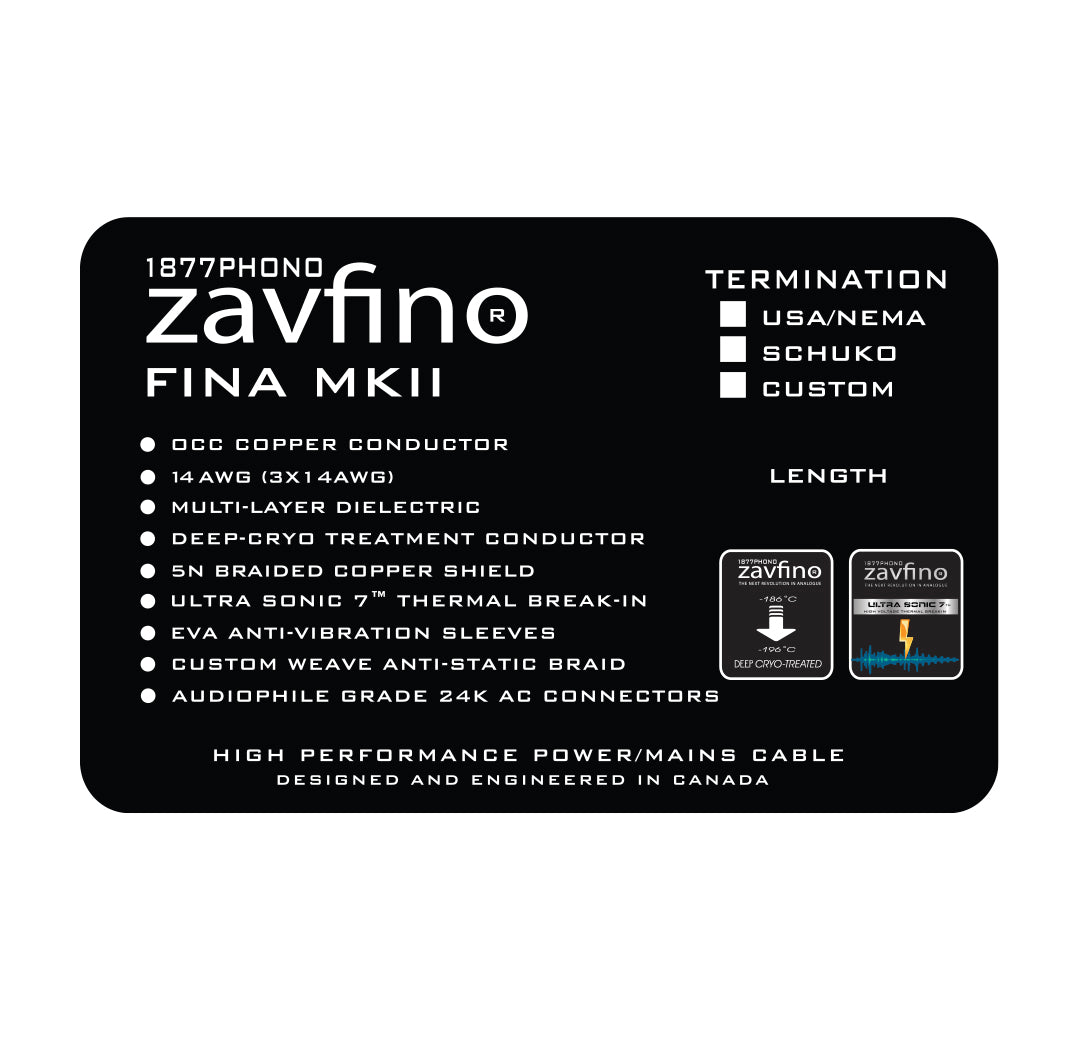

● PC-OCC Single Crystal 6N Copper Conductor

● 14AWG/Core (3X14AWG)

● Tight Pitch Twist Stranding

● 105ºC degree PVC

● Cotton filler insulation

● Full coverage shield and drain

● Spaced layer extrusion

● Deep Cryo Treated before extrusion

● Ultra Sonic-7™ Treatment

● Braid 1: Anti-static direct braid

● Braid 2: (PET) Monofilament

● Diameter 16.0mm

● Connectors: 24k gold plated IEC, 24k gold plated USA

● Lengths: 1.5-5.0 meter

C7 IEC on Request

All of the conductors used in our cables undergo Deep Cryo™ treatment before the insulation is extruded over the metals. Our research has proven that the conductor—and only the conductor— benefits from cryo-treatment. Materials such as polyvinyl chloride (PVC™), Teflon™, PE, and Silicon™ can all be adversely affected by cold-temperature annealing. Cryo-treating non-conductors and insulating materials can cause them to break down and become brittle.

The purity, size, and molecular structure of each conductor determine the specific temperature within the -186ºC to - a 196ºC range that we cryo-treat it at. Zavfino’s research into cold temperature physics has proven that the absolute lowest temperature is not necessarily the best for cryo-treatment.

This is a two-stage process. In the first stage we draw the bare conductor through a ceramic die into an ultrasonic cleaning chamber that bombards the conductor with multiple ultrasonic frequencies. This emulsification process removes all debris from the surface of the wire down to the molecular level and leaves absolutely zero residues.

UltraSonic 7 High Voltage / Thermal Break-in

This is a two-stage process. In the first stage we draw the bare conductor through a ceramic die into an ultrasonic cleaning chamber that bombards the conductor with multiple ultrasonic frequencies. This emulsification process removes all debris from the surface of the wire down to the molecular level and leaves absolutely zero residues. After each individual wire is processed, we strand it into bundles and then subject the bundles to further treatment. During the second stage of the ultrasonic burn-in, we increase the voltage to a higher level that’s just below the threshold of the conductor. This adjustment in temperature allows us to get a unique “break-in effect” normally associated with cables that have had 30 to 40 hours of signal and/or current run through them.