The Legion's core design utilizes high purity OFHC wire bundles in a tight pitch construction. We chose OFHC, as the core conductor as it was the premium choice for many High End and Exotic European made amplifiers from the mid 80’s until the late 90’s and has a unique sonic signature which cannot be easily duplicated.

Legion’s conductors are Cryo-Treated before extrusion then undergo our thermal cleaning process to remove any external dirt, oils, or drawing residue from the conductor surface. This high voltage cleaning also puts a continuous voltage through the cable giving the Legion a sound and performance of a cable, which has been run-in for many months.

Our spaced layer “cable in cable” technique insulates this cable to an overall diameter of 23mm using a power cable inside a power cable design that is uniquely our own and adding to Legion’s signature sound. When designing the Legion we took great care in designing shielding that does not choke your system or interfere or limit the power flow to components.

The optimal pairing for Legion are amplifiers, tube amps, and high power flow components. Legion is not limited to just vintage equipment and many of our clients swear by its sound when it comes to using it with some today’s most elite components. The Legion exudes power and grace allowing your system to feel unconstrained, and nourished with the correct amount of pure and steady power it demands.

SPECIFICATION● 99.998% OFHC Copper

● 11AWG/Core (3X11AWG)

● Cryo-Treated Conductor

● High voltage thermal break-in

● 6 core cotton filler insulation

● 105C degree PVC

● Tight Pitch Stranding

● Full coverage shield

● Spaced layer extrusion 6mm

● Double layer PVC extrusion

● Anti-static direct braid jacket

● Diameter 23.0mm

● Connectors: 24k gold plated IEC, 24k gold plated USA or Schuko plug

● Lengths: 1.5-2.5 meter

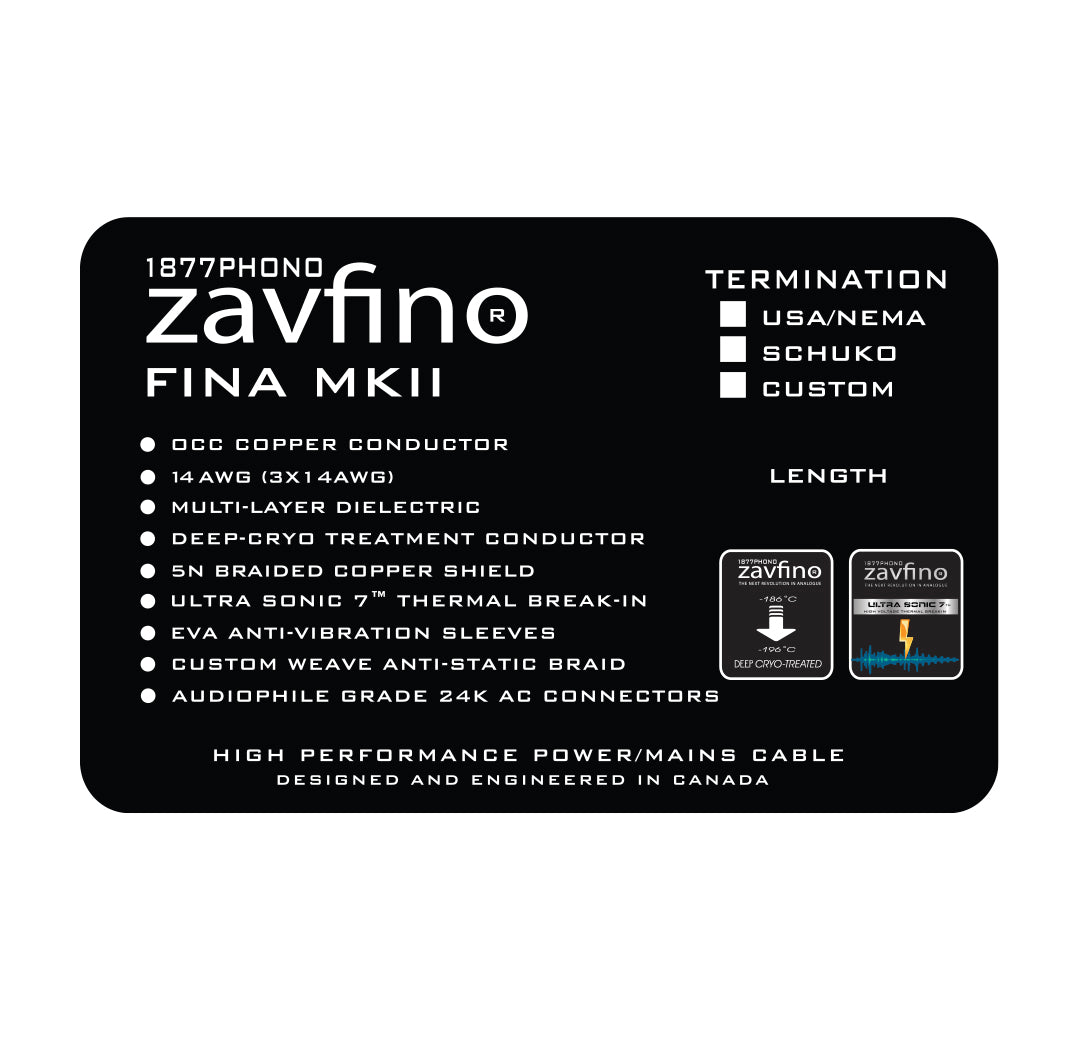

Deep Cryo™ Treatment

All of the conductors used in our cables undergo Deep Cryo™ treatment before the insulation is extruded over the metals. Our research has proven that the conductor—and only the conductor— benefits from cryo-treatment. Materials such as polyvinyl chloride (PVC™), Teflon™, PE, and Silicon™ can all be adversely affected by cold-temperature annealing. Cryo-treating non-conductors and insulating materials can cause them to break down and become brittle.

The purity, size, and molecular structure of each conductor determine the specific temperature within the -186ºC to - a 196ºC range that we cryo-treat it at. Zavfino’s research into cold temperature physics has proven that the absolute lowest temperature is not necessarily the best for cryo-treatment.

This is a two-stage process. In the first stage we draw the bare conductor through a ceramic die into an ultrasonic cleaning chamber that bombards the conductor with multiple ultrasonic frequencies. This emulsification process removes all debris from the surface of the wire down to the molecular level and leaves absolutely zero residues.

UltraSonic 7 High Voltage / Thermal Break-in

This is a two-stage process. In the first stage we draw the bare conductor through a ceramic die into an ultrasonic cleaning chamber that bombards the conductor with multiple ultrasonic frequencies. This emulsification process removes all debris from the surface of the wire down to the molecular level and leaves absolutely zero residues. After each individual wire is processed, we strand it into bundles and then subject the bundles to further treatment. During the second stage of the ultrasonic burn-in, we increase the voltage to a higher level that’s just below the threshold of the conductor. This adjustment in temperature allows us to get a unique “break-in effect” normally associated with cables that have had 30 to 40 hours of signal and/or current run through them.