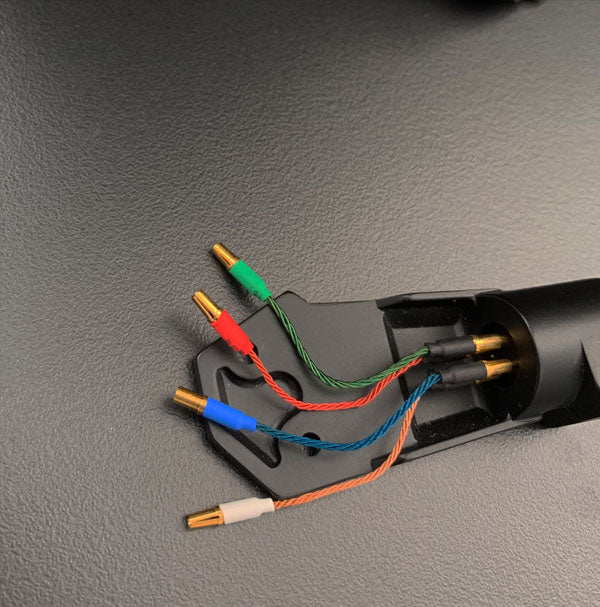

Ultra fine 34 AWG internal use tonearm wire constructed of Solid Pure Silver Strands in our H-Wound Enamel™ Litz Construction. High temperature resistant enamel film dielectric. Used by many famous manufacturers, technicians and audiophiles worldwide as the first choice in wiring, upgrading or repairing tonearms.

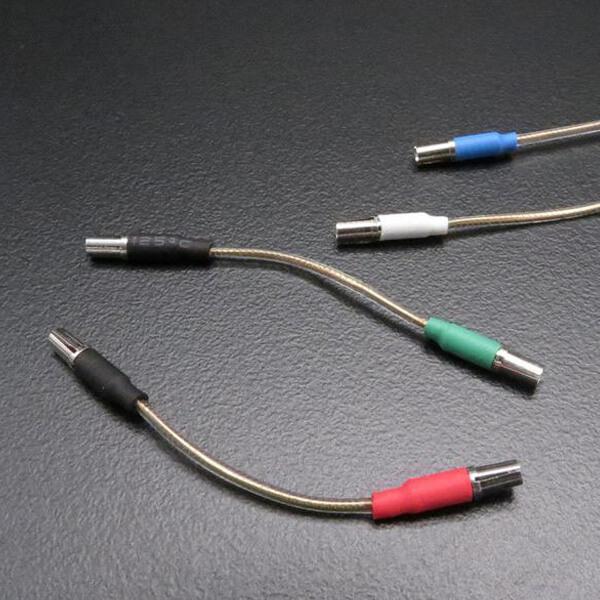

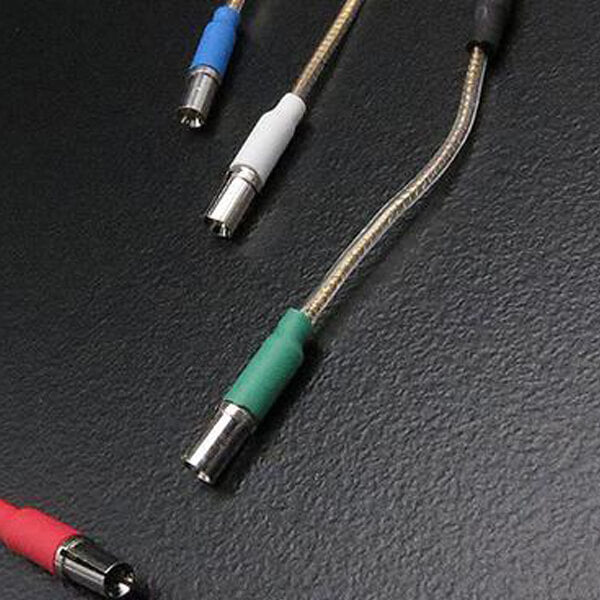

Our twisting technique also ensures each wire is 100% identical without strand lost, or the pitch becoming loose or out of alignment.

SPECIFICATION

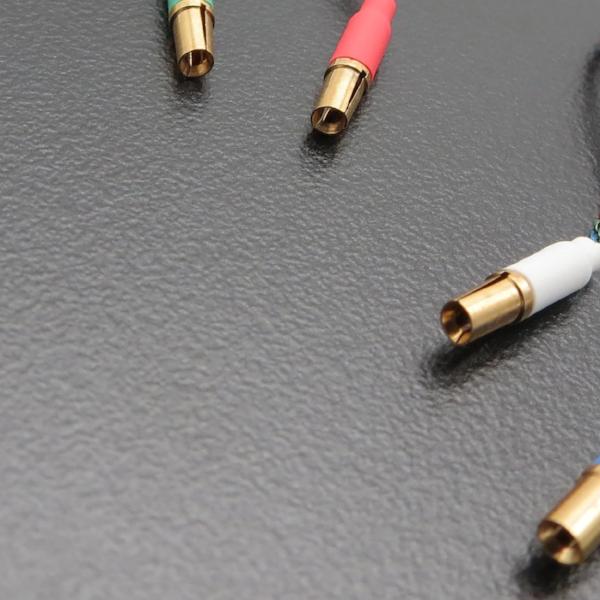

- Conductor: 99.999% Solid Pure Silver Strands

- 34AWG (4 individual 60cm cores)

- High frequency Litz construction

- Advanced polyurethane enamel film coating /Temp Res: 155Cº

- H-Wound ™ Horizontal slow feed tight pitch processing

- Overall diameter per core : 0.143mm

Zavfino’s H-Wound™ + Zero Strand Loss:

Drawing on more than 18 years of manufacturing experience, Zavfino has developed a remarkable new technique for twisting stranded wire tightly around a central solid-core conductor. An electrical phenomenon commonly known as the “skin effect” occurs when electrons move through any solid core conductor. Higher frequencies travel along the outside (the skin) of the conductor faster than midrange and lower echelon frequencies. This results in smeared PRaT, muddled instrumental timbres, and an unnatural sound. Zavfino’s new H-Wound™ manufacturing technique negates the skin effect. Originally developed by OEMs Siemens and Klangfilm, Zavfino uses a customized transformer wire-stranding machine. We further modified the gears in this machinery to create windings at a slower RPM ratio with a much tighter pitch. This patented manufacturing process enables us to twist the wiring at the tightest pitch possible without overlapping the wire strands. Most wire-stranding machines can only fabricate windings up to a maximum of 300 twists per meter. Setting the bar far higher, Zavfino’s patented H-Wound™ cable winding machine creates a pitch rate of 14,000 to 16,000 twists per meter; which is unmatched by any other audiophile cable maker. Zavfino’s new Zero Strand Loss™ manufacturing technique protects the bundled conductors from being damaged during stripping and termination. By ensuring that each core has zero chipped, cut, or mangled strands, we can guarantee that each insulated core is 100% identical. For audiophiles, the sonic results of tighter windings and Zero Strand Loss™ conductors are cables with quieter backgrounds, remarkable timbral accuracy, lifelike PRaT, jaw dropping mid-range resolution, and superior low frequency extension. Our new H-Wound™ stranding technology allows us to protect the delicate electrical signal being transferred through our cables. Combined with Zavfino’s state of the art manufacturing techniques, our precision matched OCC Copper (Cu) and Silver (Ag) conductors used in the Silver Dart™ Series of cables bring an unequalled purity and honesty to all forms of music. The results are previously unheard details, finesse, and accuracy across the frequency spectrum.